Among several related objectives, one of the most important for the NH Association of Career and Technical Administrators (NHCTA) is to form meaningful partnerships with industry. One such partnership is with the Whelen Engineering Company, Inc, which will host a meeting on March 9 at its manufacturing facility in Charlestown, NH with CTE directors and principals from schools across the state.

According to Whelen Engineering’s Jerry Maslan, who noted their company’s leadership and management will also be present, the purpose of the meeting is three-fold.

“We can discuss what is currently working, what can be improved on, and how we can adjust the curriculum to better meet the needs of manufacturing,” he said.

According to Maslan, the need to continue to leverage—and build upon—current relationships with CTE centers, each of which is charged to prepare high school students for careers—has never been greater.

“As the industry becomes automated, there doesn’t seem to be enough people or students coming up prepared or willing to run the machines,” he said.

The question as to how they increase the technical pool of available students is as much practical as it is rhetorical, which Maslan attributes to several possible causes.

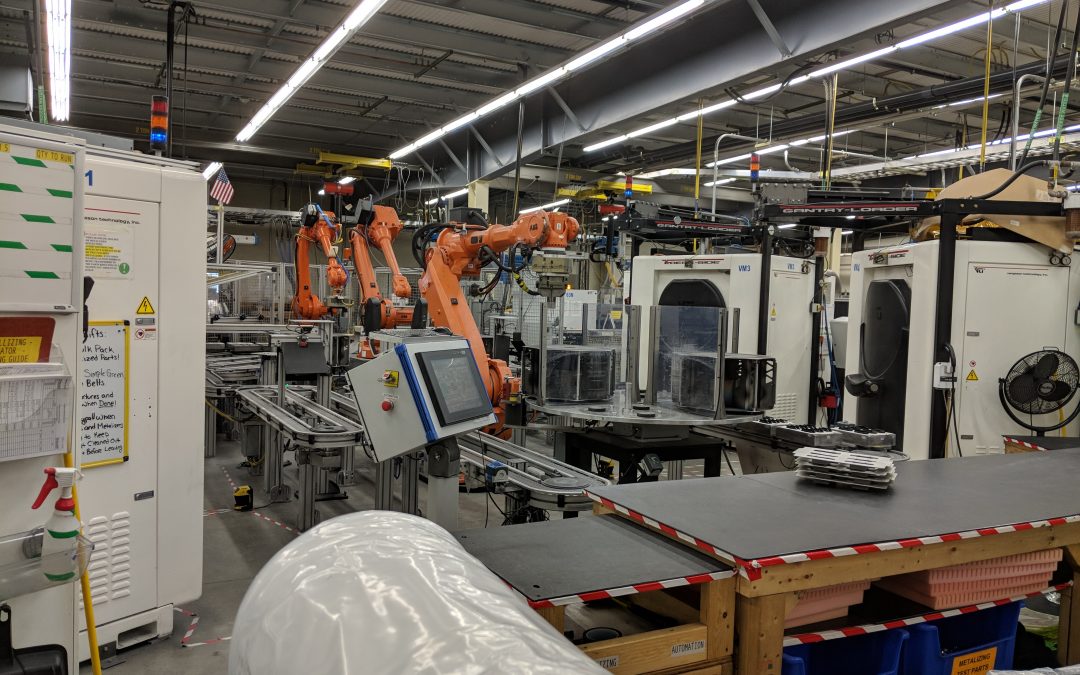

“It may be a lack of understanding of the current manufacturing world,” he explained. “It could be a stereotype where manufacturing facilities are seen as ‘old dirty machine shops,’ which is not true at all.”

He said what is true is that modern day manufacturing facilities are “state of the art and clean,” which he noted Whelen Engineering makes clear during periodic tours they host for students, teachers and administrators.

“A lot of the feedback we get from students is that this place is not what they thought it would be,” he said.

Headquartered in Chester, CT, but employing 1,000+ in Charelestown, Whelen Engineering expects the future in manufacturing to be as bright, if not brighter, than the present. Given this bright future, Maslan said it is critical they continue to work with CTE centers, administrators and various related agencies.

“It’s important to have these relationships so students, teachers and administrators can get a true understanding of current manufacturing needs,” he said. “We need to focus on the STEM education systems in schools so we can better prepare students for what lies ahead and get them excited for the opportunities that are there for them today and tomorrow.”

As for the agenda at this meeting, Maslan said they plan to cover a variety of topics that may be broken down into different areas:

From a general career pathways standpoint

- What does Whelen Engineering value in staff?

- What does Whelen Engineering value in skills including degrees and certificates?

- What background does Whelen Engineering seek for employees?

- How does Whelen Engineering support employees going on with their education while

- employed? What are current employees doing?

- What career tracks are available at Whelen Engineering? For example, from machine

- operator to programmer to product engineer? In addition, what kind of support careers

- and jobs are available (accounting, culinary…)?

From an employment standpoint?

- Who makes it at Whelen Engineering? Who does not?

- How does someone gain employment there? What is the process?

- How does the outside workforce align to Whelen Engineering’s needs?

- How do you recruit? What works? What does not?

- What does the future look like with regard to growth and possible needs?

- How does hiring from within work? What are career tracks at Whelen Engineering?

Math and Science at Whelen Engineering

- What examples of skills are worth hearing?

- What particular math and science skills are of interest? What needs emphasis?

General K-12 Education

- How can we better prepare students?

- What are we missing?

- What are we doing well? What is getting better?

- What message does Whelen Engineering want to send to public schools including school counselors? admin? teachers? parents? Kids? CTE?

- Cultural: Where do parents fit in to understanding advanced manufacturing?

How does Whelen Engineering educate their incoming and current workforce?

- Example: Knowledge of math – trig vs. calculus; reading, writing

- Retraining and refocusing?

- What does it look like? What does a training day like?

- Who is eligible – what skills are tested beforehand?

According to Maslan, various department managers will also be present at the meeting, which underscores Whelen Engineering’s belief in its fundamental importance.

“Having the people who run these departments at the meeting is very important,” he said. “They know current needs and can work with the CTE directors and principals to adapt their education systems to meet industry needs…It’s about getting the right people in the right room at the right time…we are all committed.”

To learn more about Whelen Engineering, visit www.whelen.com.