CTE Centers Adapt, Integrate New Educational Technologies

In response to the pandemic in 2020, many Career and Technical Education (CTE) centers in New Hampshire began to look at ways to integrate cutting edge technology into its programs.

“Investments in technology have enabled us to create interactive and virtual educational experiences for students,” noted Vaso Partinoudi, director of Career and Technical Education, Milford High School & Applied Technology Center.

She said the challenge to creatively engage students is heightened in CTE programs.

“Our whole focus is to provide experiential and technical training to high school students that prepares them for college and careers,” she said. “This type of learning is hands-on, which is difficult to achieve when you cannot physically get together.”

Emerging online educational learning platforms like Newsela, Pear Deck and Nearpod, however, have provided teachers with the ability to virtually engage students in new ways. Tammy Andrew, a computer science teacher at Milford High School who teaches several CTE classes, cited her use of Nearpod as one example.

“Nearpod enables me to make nearly any educational resource — PowerPoints, Google Slides, or any video — interactive,” she said. “Students can personally or anonymously respond to a video, for instance, and share responses. Students can respond to each other, too.”

In a computer programming class, Andrew said students can begin an assignment on a piece of paper or a Google document. If students are visual, they can use their cell phone or camera to submit an assignment. A digital timer, which can be turned off by the student, provides a countdown for those that require it.

“Students have a voice in how they learn,” said Andrew.

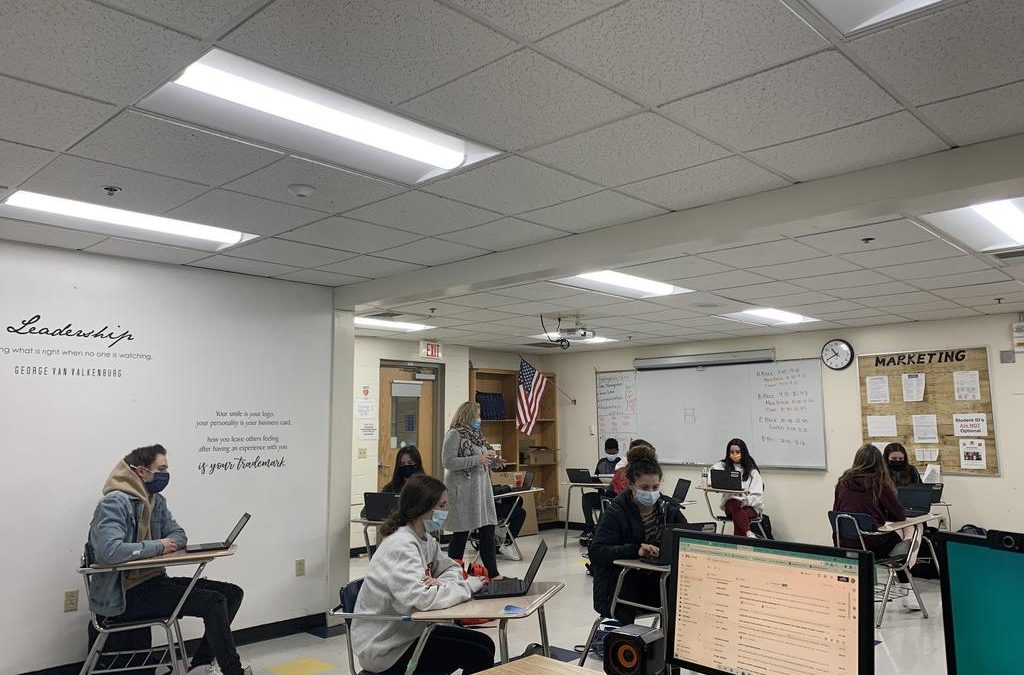

At the height of the pandemic, Kim Daniels, marketing educator at Milford High School & Applied Technology Center, said Nearpod helped teachers conduct synchronous lessons while all students were remote.

“Nearpod allows a teacher to cast a PowerPoint on the students device that the teacher controls,” she said. “It also allows for quick check-ins for understanding through a variety of activities that the students can engage in together as a class, even though they are at home learning alone.”

According to Andrew, the pandemic has accelerated the technology adoption rate by school districts.

“We are two to three years ahead of where we would be otherwise if it were not for COVID-19,” she noted. “We are pushing the abilities of Zoom, Canvas and Nearpod into the future because we need these things now.”

Such technologies, while enhancing CTE, cannot replace hands-on lessons and work-based learning.

“A computer is not a substitute for face to face learning,” Daniels said. “The opportunity to provide instant feedback and offer corrections while we watch students work is missing during remote work days.”

Jen Haskins, president of the New Hampshire Career and Technical Administrators Association, agreed and said all CTE centers statewide are “creatively working” to meet the need for experiential learning in the state.

“We continue to work with many stakeholders, including industry partners, to provide students with real-world learning opportunities like apprenticeships and internships,” she said. “With the aging of New Hampshire’s workforce and the ongoing pandemic, CTE is more important than ever.”

Milford High School & Applied Technology Center is one of 28 CTE centers throughout New Hampshire.