Mar 30, 2018 | Manufacturing Technology/Technician, Tid Bits, Welding Technology

The Barrington Police Department needed pass through lockers for evidence collection. Lockers will be installed into a wall where officers will place seized evidence into the locked lockers on the outside and the people working inside can collect the items in the morning. These are usually very expensive, but the Seacoast School of Technology Welding Technologies students were able to fabricate them for just over a $100!

Mar 30, 2018 | Article

On May 29th, a packed house is expected at Pinkerton Academy from 6 to 9 pm in the Stockbridge Theatre for the first annual SAFETEEN Awards and Film Festival.

At the event, awards will be given out I various categories, some of which include: Best Fire Safety Film, Best Suicide Prevention Film, Best Substance Abuse Film, and Best Non-Traditional Workplace Awareness Film. According to Chris Lord, video production teacher at Pinkerton Academy, the event is a unique opportunity for high school film makers to receive recognition in a subject that often has people reaching out to him.

“Each year as a video production teacher, I get several requests for projects pertaining to teen safety,” he said. I get requests for PSA’s, short films, music videos, commercials and campaigns. They come in from both internal and external sources pertaining to teen safety—school clubs, local not for profit associations, various departments at school, local fire and first responders.”

He said a lot of these requests are in support of Teen Dating Violence Awareness Month, Self Harm Awareness Month, National Youth Violence Prevention Week, Youth Sports Safety Month and others.

“From this, I knew there would be fantastic content at schools around the state and a need for a festival like this one,” said Lord, who noted it is also not too late for high school students statewide to submit a video for consideration.

“The submission deadline is fast approaching for April 10th,” he said. “I have reached out to many video teachers myself but wanted to make sure all CTE centers are aware—We have a lot of sponsors, trophies and prizes, too.”

The event is expected to attract a large audience with everyone from experts in various fields of safety to NH Senators and perhaps the Governor—all of whom have expressed a desire to honor students contributing to teen safety.

In expressing excitement for the event, Lord said he also feels it helps to highlights some larger societal issues.

“I think many teens have been emotionally disturbed by the rise in school shootings, opioid addiction, and bullying as well as in the increasing disconnect and hardened discourse on these topics,” he said.

My hope is that a celebration of teens caring about other teens’ safety and celebrating teens doing things to help one another to be happier, healthier, and safer will lead toward building positive discourse and care for everyone’s safety.”

As for content at the show, he anticipates a mix of groups of nominated student films organized by respective safety messages with presentations by first responders and other safety stakeholders from across the state.

“Awards will be given to recognize top film projects and to recognize students that have contributed to teen safety in various ways during the past year,” said Lord. “The hope is to make this an annual event that celebrates teen safety.

To learn more, visit www.safeteenfilm.com. To submit a video, visit https://filmfreeway.com/SAFETEEN.

Mar 13, 2018 | Article

In an industry that is expected to keep booming for years, careers in heating, ventilation, and air conditioning (HVAC) are not only desirable, but lucrative.

According to local HVAC companies actively involved in the Program Advisory Board at Manchester Community College (MCC), the current annual salary for an experienced HVAC Technician is about $70k. By 2020, it is projected to be around $100k.

In response to this need, MCC established an initiative that enables NH high school students to take MCC classes at 50% of the tuition per course. According to Eddie Curran, HVAC Department Chair at MCC, the initiative is known as Early College, which includes 4 program tracks: HVAC, Advanced Manufacturing, Allied Health, and Computer Science.

In the HVAC track, additional savings are realized for students, as courses are free through the Governor’s STEM Scholarship program. In addition, HVAC students—either in a CTE program or not—can earn up to 18 college credits while still in high school.

“Over the course of the 4 semesters, the students will pay just $1,000 for 18 college credits,” he said. “18 credits is almost one-third of the way toward an Associate’s degree here—there’s amazing value in that.”

For students (or parents) who may not necessarily think a career in HVAC is either exciting or cutting-edge, Curran said nothing could be further from the truth.

“It is extremely technical,” he said. “It’s definitely not turning wrenches. You have to have formal training—and a lot of it is computer-based.”

According to Curran, the Early College HVAC program at MCC is part of a larger academic pathway.

“After you earn an Associate’s degree, you can earn an advanced certificate to work on more complex equipment,” he said. “We also have an agreement with Southern New Hampshire University and Granite State College where someone can take 8 classes after that and get a BA in management…The majority of someone course, though, can be taken at MCC.”

Similar to the Running Start program in that students can earn college credits in high school, Early College differs in one important respect, as classes are taught by college professors on the MCC campus. In Running Start, another difference is that classes are taught by high school instructors.

“With Early College, you get the college experience and mentoring opportunities by college students,” added Curran. “We have also built into the HVAC program dedicated tutoring support so we can help students succeed and do well.”

As to the future of the program, Curran cited a need to engage in concerted outreach with one of his first forays into the larger educational community an upcoming guidance counselor breakfast on March 22 at MCC.

“It’s for high school counselors to inform them of the opportunities of Early College so they can share it with their schools and students,” he said.

Noting there are just 5 CTE programs in the state that offer an HVAC program, Curran said the need for technicians in NH has never been greater.

“With this program, MCC essentially becomes another CTE option for the high schools,” he said. “The cost of running a CTE HVAC program is very expensive for schools. Now, they don’t need a lab or a budget for it, because we can be that option for their students…We expect a lot of interest in this program.

For those with questions about the HVAC Early College Program, contact Curran at (603) 206-8041 or ecurran@ccsnh.edu.

Mar 7, 2018 | CTSO, SkillsUSA NH, Tid Bits

SkillsUSA New Hampshire in partnership with the Manchester Monarchs is pleased to announce SkillsUSA New Hampshire Appreciation Night at the Manchester Monarch’s on April 7, 2018 at 6:00pm. SkillsUSA Members, Advisors, Business Partners, Alumni, Family and Friends are all invited to attend this wonderful event. The cost per ticket is $10.00 (Normally $25.00). Come celebrate a night of fun and company as we celebrate the success of the 2018 State Conference and the 2017-2018 School Year. Let’s pack the house !! Tickets

Feb 28, 2018 | Article

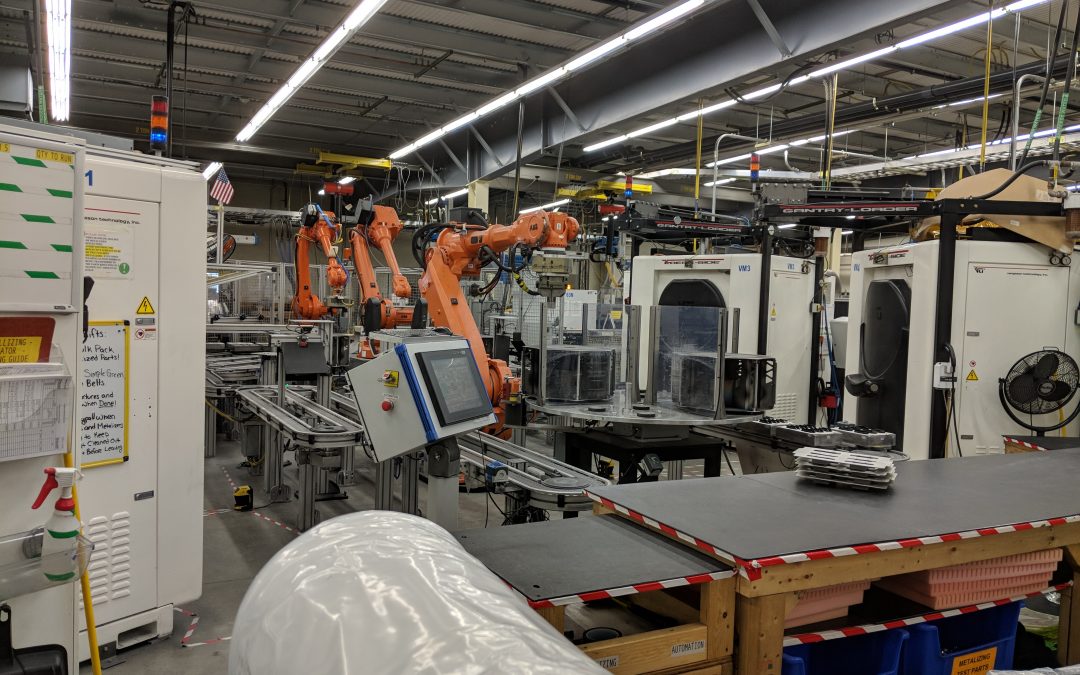

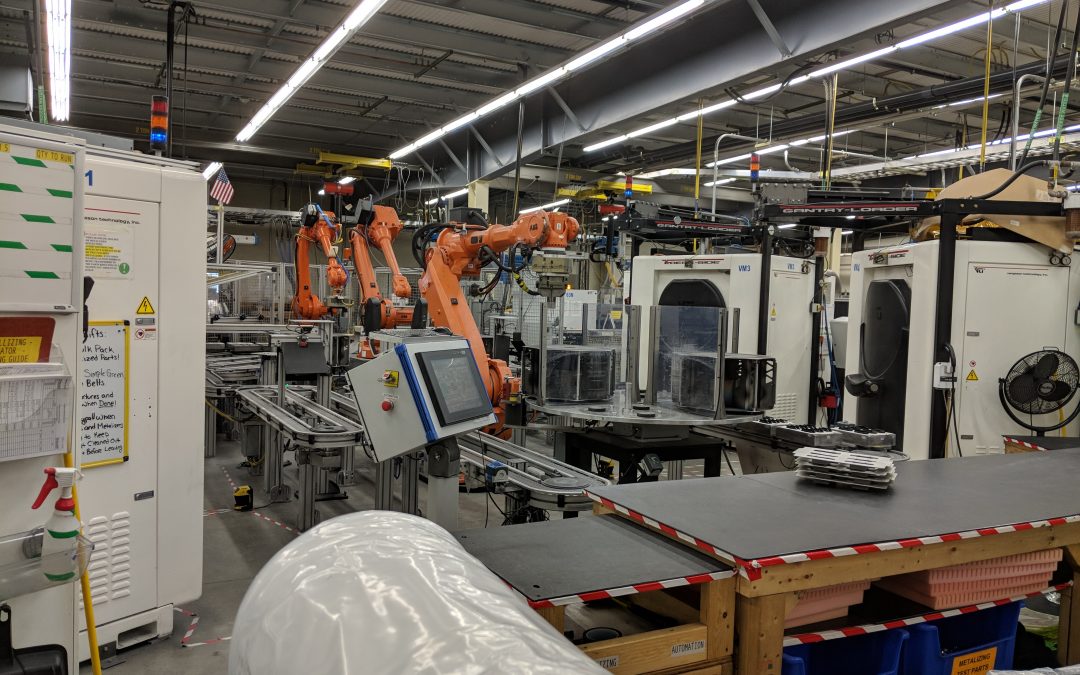

Among several related objectives, one of the most important for the NH Association of Career and Technical Administrators (NHCTA) is to form meaningful partnerships with industry. One such partnership is with the Whelen Engineering Company, Inc, which will host a meeting on March 9 at its manufacturing facility in Charlestown, NH with CTE directors and principals from schools across the state.

According to Whelen Engineering’s Jerry Maslan, who noted their company’s leadership and management will also be present, the purpose of the meeting is three-fold.

“We can discuss what is currently working, what can be improved on, and how we can adjust the curriculum to better meet the needs of manufacturing,” he said.

According to Maslan, the need to continue to leverage—and build upon—current relationships with CTE centers, each of which is charged to prepare high school students for careers—has never been greater.

“As the industry becomes automated, there doesn’t seem to be enough people or students coming up prepared or willing to run the machines,” he said.

The question as to how they increase the technical pool of available students is as much practical as it is rhetorical, which Maslan attributes to several possible causes.

“It may be a lack of understanding of the current manufacturing world,” he explained. “It could be a stereotype where manufacturing facilities are seen as ‘old dirty machine shops,’ which is not true at all.”

He said what is true is that modern day manufacturing facilities are “state of the art and clean,” which he noted Whelen Engineering makes clear during periodic tours they host for students, teachers and administrators.

“A lot of the feedback we get from students is that this place is not what they thought it would be,” he said.

Headquartered in Chester, CT, but employing 1,000+ in Charelestown, Whelen Engineering expects the future in manufacturing to be as bright, if not brighter, than the present. Given this bright future, Maslan said it is critical they continue to work with CTE centers, administrators and various related agencies.

“It’s important to have these relationships so students, teachers and administrators can get a true understanding of current manufacturing needs,” he said. “We need to focus on the STEM education systems in schools so we can better prepare students for what lies ahead and get them excited for the opportunities that are there for them today and tomorrow.”

As for the agenda at this meeting, Maslan said they plan to cover a variety of topics that may be broken down into different areas:

From a general career pathways standpoint

- What does Whelen Engineering value in staff?

- What does Whelen Engineering value in skills including degrees and certificates?

- What background does Whelen Engineering seek for employees?

- How does Whelen Engineering support employees going on with their education while

- employed? What are current employees doing?

- What career tracks are available at Whelen Engineering? For example, from machine

- operator to programmer to product engineer? In addition, what kind of support careers

- and jobs are available (accounting, culinary…)?

From an employment standpoint?

- Who makes it at Whelen Engineering? Who does not?

- How does someone gain employment there? What is the process?

- How does the outside workforce align to Whelen Engineering’s needs?

- How do you recruit? What works? What does not?

- What does the future look like with regard to growth and possible needs?

- How does hiring from within work? What are career tracks at Whelen Engineering?

Math and Science at Whelen Engineering

- What examples of skills are worth hearing?

- What particular math and science skills are of interest? What needs emphasis?

General K-12 Education

- How can we better prepare students?

- What are we missing?

- What are we doing well? What is getting better?

- What message does Whelen Engineering want to send to public schools including school counselors? admin? teachers? parents? Kids? CTE?

- Cultural: Where do parents fit in to understanding advanced manufacturing?

How does Whelen Engineering educate their incoming and current workforce?

- Example: Knowledge of math – trig vs. calculus; reading, writing

- Retraining and refocusing?

- What does it look like? What does a training day like?

- Who is eligible – what skills are tested beforehand?

According to Maslan, various department managers will also be present at the meeting, which underscores Whelen Engineering’s belief in its fundamental importance.

“Having the people who run these departments at the meeting is very important,” he said. “They know current needs and can work with the CTE directors and principals to adapt their education systems to meet industry needs…It’s about getting the right people in the right room at the right time…we are all committed.”

To learn more about Whelen Engineering, visit www.whelen.com.