May 6, 2018 | Article

Reflecting its mission “to provide education, leadership, and support for the profession of Engineering across all disciplines of practice,” the New Hampshire Joint Engineering Societies (NHJES) is inviting students to its annual fall conference in October.

NHJES is made up of organizations such as; Structural Engineers of New Hampshire (SENH), Society of Women Engineers (SWE), American Council of Engineering Companies (ACEC), Institute of Electrical and Electronics Engineers (IEEE), and many more.

According to NHJES Board Member Frank Xydias, engineering instructor at Milford High School & Applied Technology Center in Milford, participation in the conference will provide students with a unique opportunity.

“It is not often that high school students have the opportunity to attend a professional workshop and present their concepts in a real-world application,” he said.

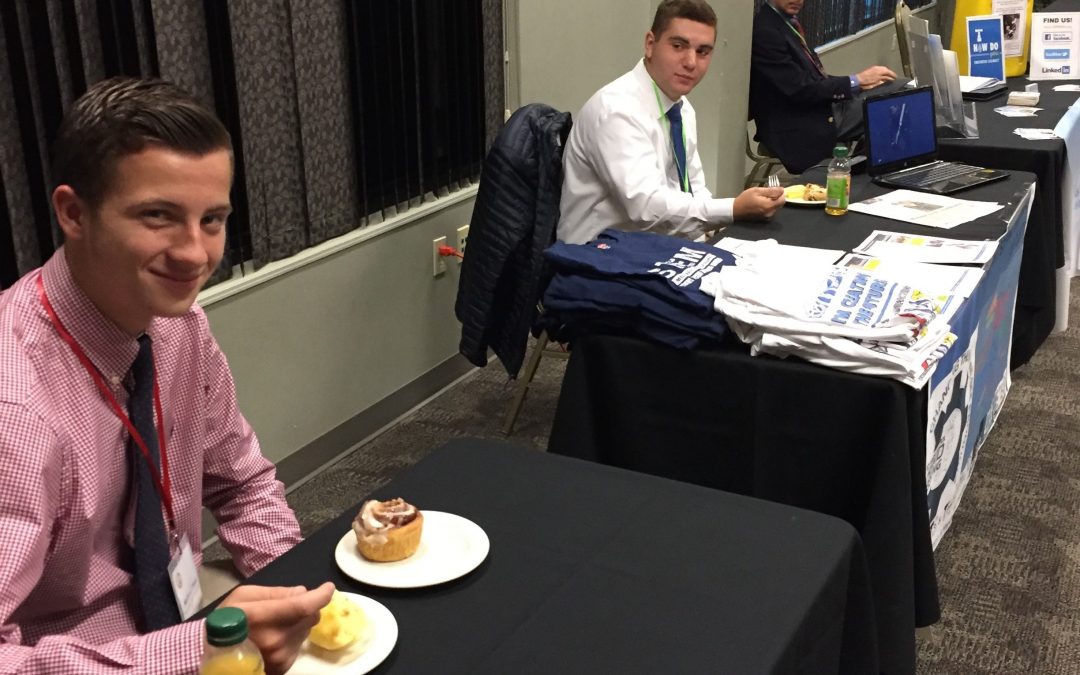

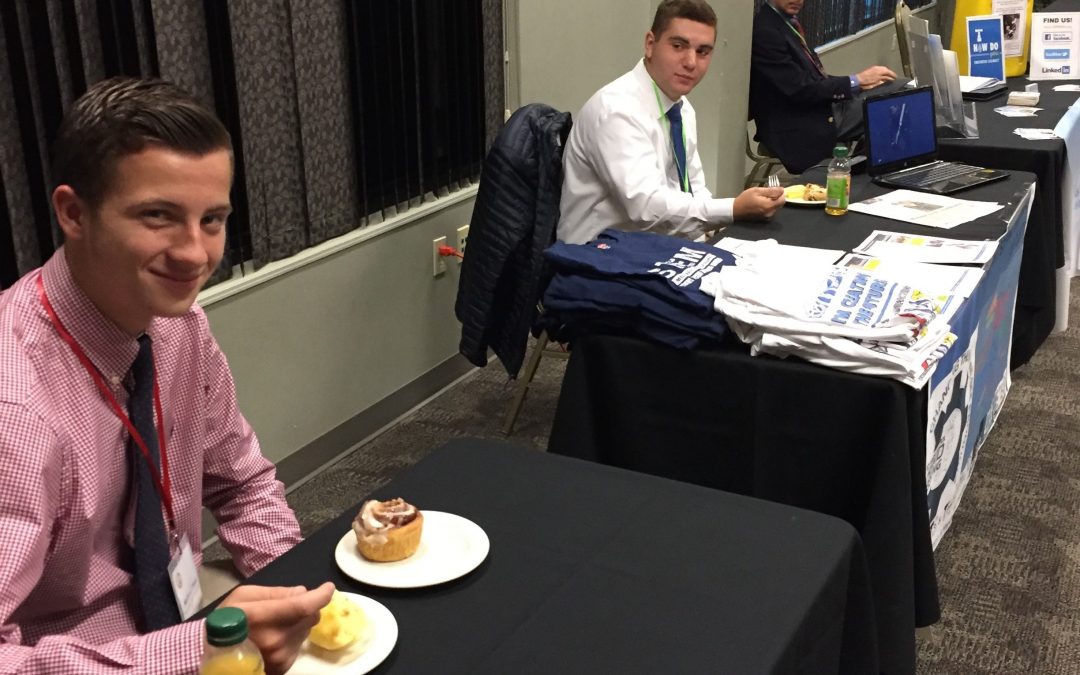

This year’s invitation follows a similar one for last year’s conference in which Milford students attended workshops and breakout sessions. In addition, students Matthew Chase and Nikolas Liamos brought their prosthetic bike project to showcase at the 2017 NHJES conference.

One change this year, however, is that the invitation is statewide and open to 12 different STEAM/STEAM groups. Xydias noted the grand vision for this year is to host 12 different groups that include 3 students and 1 teacher from the following groups: PLTW, VEX Robotics, US First Robotics, DOT TRAC, Young Inventors, or others. At this event, they will set up a table display with their projects.

“It is important for students to see the natural progression from interest to career and ways to support those careers through professional networks,” he said.

At the conference, high school students will also be able to learn about current technology and trends happening in industry.

“We ultimately hope these high school students will become members of NHJES or other professional organizations so they can give back in ways they received,” said Xydias. “We want them to see the value in collaboration and on-going training and education.”

He said there is also an immediate experiential learning component for students who attend the conference.

“Matthew and Nik arrived on-time at last year’s conference and ready to work,” he said. “In professional collars, shirt and tie, they greeted passers-by and talked about their project. It was the type of environment that challenged them to think about “why” and answer common questions about it, which is exactly what they will encounter in the engineering design process…It was a ‘text book’ idea board of sharing, but we were not in a classroom.”

These real world tests, noted Xydias provide students with valuable, potentially life-changing insight(s).

“Professional networking is a big part of this and other industries,” he said. “This conference can provide budding engineers with an inside glimpse into this world, a chance to talk to veteran engineers and learn from people in the industry today.”

To learn more about the conference, which takes place on October 9 in Concord and is supported by numerous sponsors who are donating space to students, visit https://docs.google.com/document/d/1ZljhkSLKJYNw-sPMYnqC2H5gzLYS2PzCvK_1KiecNQE/edit.

To sign up, click https://goo.gl/forms/aUIWi1S3HFldPzjk2.

May 4, 2018 | Article, Building & Construction Trades, Cabinetmaking & Millwork, Drafting & Design Technology, Electrician, Heating/Air Conditioning, Refrigeration, Heavy Equipment Maintenance & Repair, Plumbing & Water Supply Services, SkillsUSA NH, Tid Bits

This year’s Construction Career Days are scheduled for September 27th and 28th from 8:30-12:30. It will be held at the Hillsborough County Youth Center Foundation in New Boston, NH. New Hampshire Construction Career Days (NHCCD) exposes New Hampshire high school students to possible career paths in both the construction and transportation industries through a hands-on exhibits and educational resources. Labor unions, construction companies, school districts, state agencies, trade and professional organizations collaborate to provide the students with an introduction to various aspects of construction.

This event increases career awareness in the construction and transportation industries through hands-on experience with heavy equipment, welding, small tools, plumbing, electrical wiring, surveying, waste water management, bridge construction, land clearing, underground utilities, and other construction related jobs. Several secondary educational resources and career training pathways are available for students to learn about. Professionals from a wide array of construction related work are available to speak with students and answer questions about their experiences in the construction industry and why they are so passionate about their career.

The day is open to all high school students, both male and female, via registration through a participating school. In fact, one of the goals of this event is to Increase the attendance of women and minorities participating in this event to a target attendance of 25%. Last year we were able to reach out to just over 14% females and 21% minorities.

Information & Registration

Apr 29, 2018 | Article

While academic debates still persist regarding whether today’s student requires more hands-on training or academic rigor to succeed as an adult, such discussions miss a key point.

“There is a real career to be had in the trades that is quite lucrative with the right education,” said Karen Machado, principal at Manchester School of Technology (MST).

In promoting the viability of Career and Technical Education (CTE) in the state, barriers extend beyond academic circles.

“There are programs where you can earn a degree to become a teacher, business manager, engineer and more, but many parents and students still do not realize that,” she said. “There is also a great salary with these jobs and many opportunities for female students, too.”

Recently featured in The Hechinger Report, MST has distinguished itself in recent years for its emphasis on creating opportunities for CTE and academic teachers to actively collaborate in educating students. As one example, Machado cited a Biology class in which a group of students had previously failed one or two times.

“They needed to experience Biology in a different manner,” she said.

At MST, this “different manner” led to a collaboration between their Horticulture teacher, who had expressed an interest in team teaching an Ecology course, and Biology teacher. The Horticulture teacher conducted the hands-on experiences outside while the Biology teacher conducted in-class direct instruction and experiments.

“Nearly all students will successfully finish this course,” said Machado. “The same was the case for our Manufacturing teacher teaching Physical Science with a Geometry teacher. Adding that relevance piece makes all the difference in the world when teaching students.”

The need for such collaborative teaching methods does not just represent best practice in the industry; rather, it addresses real needs in industry today, as she cited CTE as an important player in the state’s economic development.

“Now more than ever, businesses have a desperate need to fill these positions with the best experienced employees,” she said. “CTE will help to keep these young talented minds in the state of New Hampshire. This is so true now with the low unemployment rates. We need to keep our talent in state.”

In discussing how CTE works, Machado said it is important to note how it has changed through the years. She described it, as do most professionals in the CTE industry, as relating to “career pathways,” which are not necessarily straight or even linear.

“In our school, students who are motivated create their own pathway,” she said. “The beauty of students being at MST full-time is that they find the way to take two or three CTE programs. Sometimes, students take courses on VLACS in the summer to make room in their schedule for the needed time for CTE. Some students take architectural engineering and then go into carpentry.”

She said she has even had a student who completed two years of carpentry and then went into the Firefighter Program in the first semester and completed the EMT program in the second semester as a senior.

“One problem that has come up is that students are wanting to take a 5th year of high school to take more CTE programs,” she said. “They are truly seeing the benefit of becoming educated in high school instead of paying for it later.”

This article represents the first of several articles that will take a deeper look at MST and the larger context in which their programs have been developed to better meet the needs of students and industry.

Apr 19, 2018 | Article

Although often referred to as “soft,” teamwork, communication, problem solving and critical thinking are skills in high demand in the workplace today, which makes the NH ProStart Invitational so unique.

Held in early March at UNH, this culinary competition pits high school teams from across the state against one another, as they demonstrate these skills through the preparation of a three-course meal in 60 minutes. According to Mark Cahill, lead culinary arts instructor at Pinkerton Academy, there is several mitigating factors that make this competition particularly difficult.

“They only have access to two camp-style butane burners with no electricity or running water,” he said. “It’s intense, but the judges still expect a high-end restaurant quality menu.”

The efforts by students at Pinkerton Academy paid off, as they placed first (two years running) in the culinary division with a menu Cahill said you would expect at any fine dining establishment.

“They did an incredible job,” he said. “I’m very proud of their accomplishment.”

The Menu

Pan-Seared Hudson Valley Foie Gras

Pickled Watermelon Radish, LaBelle Blueberry Wine Soaked Cherries, Sweet Potato Nest, Caramelized Pearl Onions, Orange Liqueur Reduction

$23

Espresso-Rubbed Bison Strip Steak

Rainbow Swiss Chard, Tourne of Purple Potato, Parmesan Tuille

Samuel Smith’s Chocolate Stout Pan Sauce

$32

White Chocolate-Lavender Bavarian

Passion Fruit Infused Whip Cream, Gewürztraminer Poached Asian Pears

Spun Sugar, Honey-Wine Reduction

$12

The next stop for the culinary team, according to Cahill, is the National ProStart Invitational later this month in Providence, Rhode Island.

“We are excited,” he added.

“Managing” success

Keith Desjardin, culinary instructor at Pinkerton Academy, is also excited, as his team placed second in the management portion of the competition. In this division, students developed a restaurant concept, vetted it and presented it before a panel of hypothetical investors.

“Their concept was a restaurant in a strip mall close to a university with local artwork on the walls, a large stage for local musicians during lunch and dinner service,” he said. “They has to present their menu, floor plan and marketing strategies. They also had to answer critical thinking questions and how they would resolve certain issues.”

While initially proud of their accomplishment, Desjardin acknowledged his team was “bummed out,” however, when they discovered how close they were to actually winning and qualifying for the nationals.

“They were just .875 points down from the top spot,” he said. “It bummed them out.”

Like Cahill, his excitement regarding the competition also stems from the deeper implications regarding what it means for their future.

“Even if they don’t continue in the program here, the soft skills they have learned can be applied elsewhere,” he said.

He said it is not just about the food either.

“It’s their understanding of the financial aspect of things—covering labor and other costs,” he explained. “They are developing teamwork , interviewing and presentations skills as well as personal responsibility. They are thinking on their feet, collaborating, compromising, adapting and evolving concepts. They are learning about the importance of being on time, dressing professionally, public speaking…These are the skills employers are telling us people lack today.”

As with many CTE programs, there is strong participation from industry in the competition with Cahill noting his students already have job offers from Bobby Marcotte, program mentor and executive chef and owner of Tuckaway Tavern and Butchery in Raymond.

“He has been in Guy’s Grocery Games—he is sort of our celebrity chef in New Hampshire,” he said. “He just reached out to all my students and wants to employ all of them.”

To learn more or to become involved with NH ProStart, contact Amie Pariseau at apariseau@nhlra.com.

Mar 30, 2018 | Article

On May 29th, a packed house is expected at Pinkerton Academy from 6 to 9 pm in the Stockbridge Theatre for the first annual SAFETEEN Awards and Film Festival.

At the event, awards will be given out I various categories, some of which include: Best Fire Safety Film, Best Suicide Prevention Film, Best Substance Abuse Film, and Best Non-Traditional Workplace Awareness Film. According to Chris Lord, video production teacher at Pinkerton Academy, the event is a unique opportunity for high school film makers to receive recognition in a subject that often has people reaching out to him.

“Each year as a video production teacher, I get several requests for projects pertaining to teen safety,” he said. I get requests for PSA’s, short films, music videos, commercials and campaigns. They come in from both internal and external sources pertaining to teen safety—school clubs, local not for profit associations, various departments at school, local fire and first responders.”

He said a lot of these requests are in support of Teen Dating Violence Awareness Month, Self Harm Awareness Month, National Youth Violence Prevention Week, Youth Sports Safety Month and others.

“From this, I knew there would be fantastic content at schools around the state and a need for a festival like this one,” said Lord, who noted it is also not too late for high school students statewide to submit a video for consideration.

“The submission deadline is fast approaching for April 10th,” he said. “I have reached out to many video teachers myself but wanted to make sure all CTE centers are aware—We have a lot of sponsors, trophies and prizes, too.”

The event is expected to attract a large audience with everyone from experts in various fields of safety to NH Senators and perhaps the Governor—all of whom have expressed a desire to honor students contributing to teen safety.

In expressing excitement for the event, Lord said he also feels it helps to highlights some larger societal issues.

“I think many teens have been emotionally disturbed by the rise in school shootings, opioid addiction, and bullying as well as in the increasing disconnect and hardened discourse on these topics,” he said.

My hope is that a celebration of teens caring about other teens’ safety and celebrating teens doing things to help one another to be happier, healthier, and safer will lead toward building positive discourse and care for everyone’s safety.”

As for content at the show, he anticipates a mix of groups of nominated student films organized by respective safety messages with presentations by first responders and other safety stakeholders from across the state.

“Awards will be given to recognize top film projects and to recognize students that have contributed to teen safety in various ways during the past year,” said Lord. “The hope is to make this an annual event that celebrates teen safety.

To learn more, visit www.safeteenfilm.com. To submit a video, visit https://filmfreeway.com/SAFETEEN.

Mar 13, 2018 | Article

In an industry that is expected to keep booming for years, careers in heating, ventilation, and air conditioning (HVAC) are not only desirable, but lucrative.

According to local HVAC companies actively involved in the Program Advisory Board at Manchester Community College (MCC), the current annual salary for an experienced HVAC Technician is about $70k. By 2020, it is projected to be around $100k.

In response to this need, MCC established an initiative that enables NH high school students to take MCC classes at 50% of the tuition per course. According to Eddie Curran, HVAC Department Chair at MCC, the initiative is known as Early College, which includes 4 program tracks: HVAC, Advanced Manufacturing, Allied Health, and Computer Science.

In the HVAC track, additional savings are realized for students, as courses are free through the Governor’s STEM Scholarship program. In addition, HVAC students—either in a CTE program or not—can earn up to 18 college credits while still in high school.

“Over the course of the 4 semesters, the students will pay just $1,000 for 18 college credits,” he said. “18 credits is almost one-third of the way toward an Associate’s degree here—there’s amazing value in that.”

For students (or parents) who may not necessarily think a career in HVAC is either exciting or cutting-edge, Curran said nothing could be further from the truth.

“It is extremely technical,” he said. “It’s definitely not turning wrenches. You have to have formal training—and a lot of it is computer-based.”

According to Curran, the Early College HVAC program at MCC is part of a larger academic pathway.

“After you earn an Associate’s degree, you can earn an advanced certificate to work on more complex equipment,” he said. “We also have an agreement with Southern New Hampshire University and Granite State College where someone can take 8 classes after that and get a BA in management…The majority of someone course, though, can be taken at MCC.”

Similar to the Running Start program in that students can earn college credits in high school, Early College differs in one important respect, as classes are taught by college professors on the MCC campus. In Running Start, another difference is that classes are taught by high school instructors.

“With Early College, you get the college experience and mentoring opportunities by college students,” added Curran. “We have also built into the HVAC program dedicated tutoring support so we can help students succeed and do well.”

As to the future of the program, Curran cited a need to engage in concerted outreach with one of his first forays into the larger educational community an upcoming guidance counselor breakfast on March 22 at MCC.

“It’s for high school counselors to inform them of the opportunities of Early College so they can share it with their schools and students,” he said.

Noting there are just 5 CTE programs in the state that offer an HVAC program, Curran said the need for technicians in NH has never been greater.

“With this program, MCC essentially becomes another CTE option for the high schools,” he said. “The cost of running a CTE HVAC program is very expensive for schools. Now, they don’t need a lab or a budget for it, because we can be that option for their students…We expect a lot of interest in this program.

For those with questions about the HVAC Early College Program, contact Curran at (603) 206-8041 or ecurran@ccsnh.edu.